Mechanical components can fail in ways that are invisible to the human eye. A cracked gear tooth, a bearing seizure, or a fractured weld may occur in just microseconds, yet cause costly downtime or safety risks. High-speed filming for mechanical failure analysis captures these split-second events frame by frame, allowing engineers to pinpoint the exact causes of failure.

At thousands of frames per second, high-speed cameras reveal details that conventional inspection tools miss. This makes them invaluable for forensic engineering, root cause analysis, and non-destructive testing (NDT). With the ability to slow down motion and expose hidden processes, our systems enable engineers to:

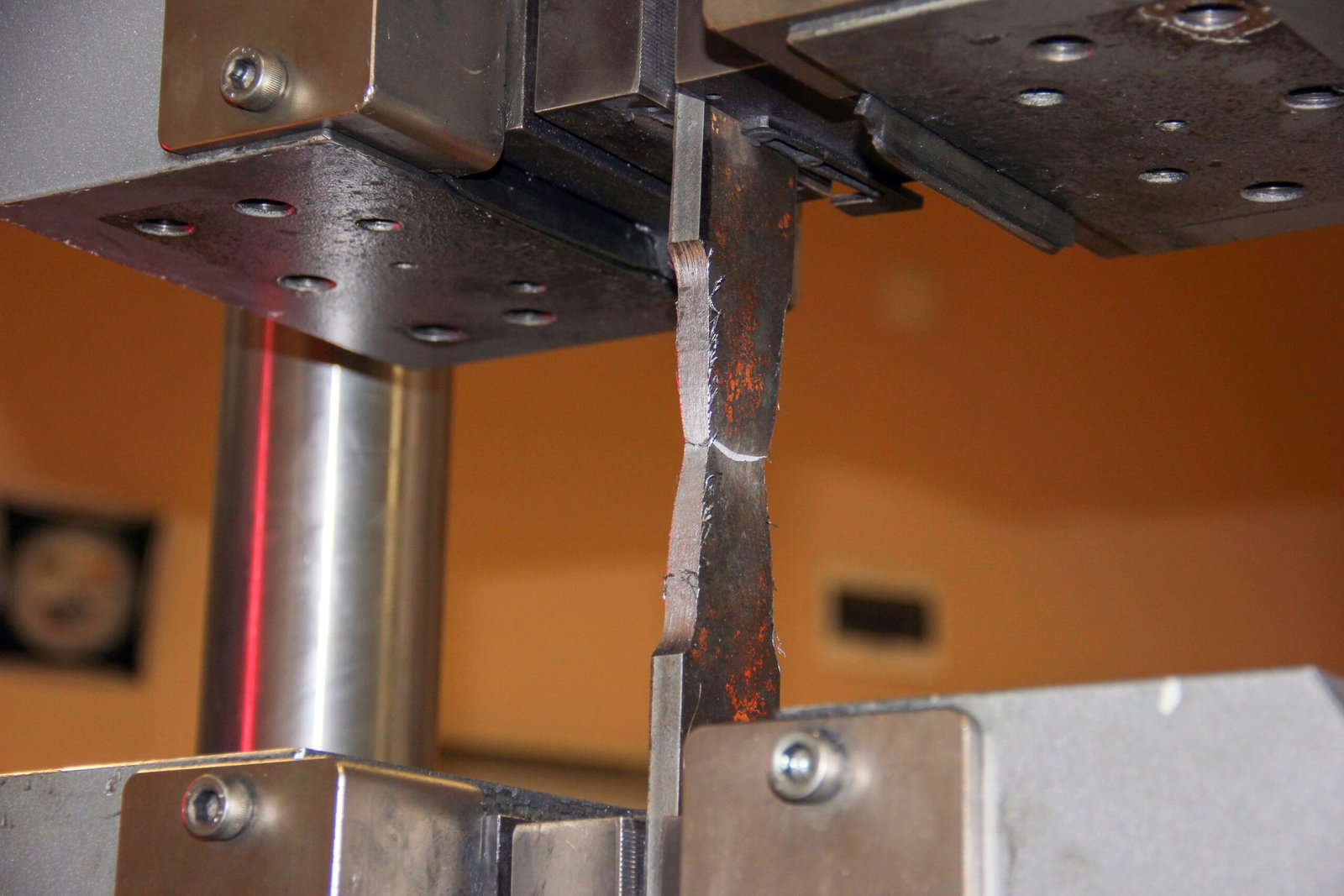

Observe crack initiation and fracture propagation

Analyse material fatigue and stress concentrations

Detect bearing, gear, and joint failures under load

Study heat, vibration, and energy transfer in components

Support predictive maintenance and product redesign

High-speed mechanical failure analysis is critical across multiple sectors:

Automotive – crash testing, safety systems, engine components

Aerospace – turbine blade fatigue, landing gear failures, structural integrity

Manufacturing – robotics, rotating machinery, heavy equipment inspection

Energy & Infrastructure – turbines, pipelines, power systems under stress

Research & Development – experimental prototypes and advanced materia

Accurate root cause identification for safer, more reliable products

Reduced downtime through early detection of weaknesses

Improved safety compliance with industry regulations

Cost savings from preventing catastrophic breakdowns

Actionable data for R&D and future product innovation

With over 20 years of experience in high-speed imaging and forensic engineering applications, we combine advanced camera systems, precision lenses, and flicker-free lighting to deliver the most accurate visual data for mechanical failure analysis. Every project is tailored to your needs, ensuring clarity, reliability, and actionable insights.